PF Winch Case Study

PF 10-250:

Performer Flying Hoist

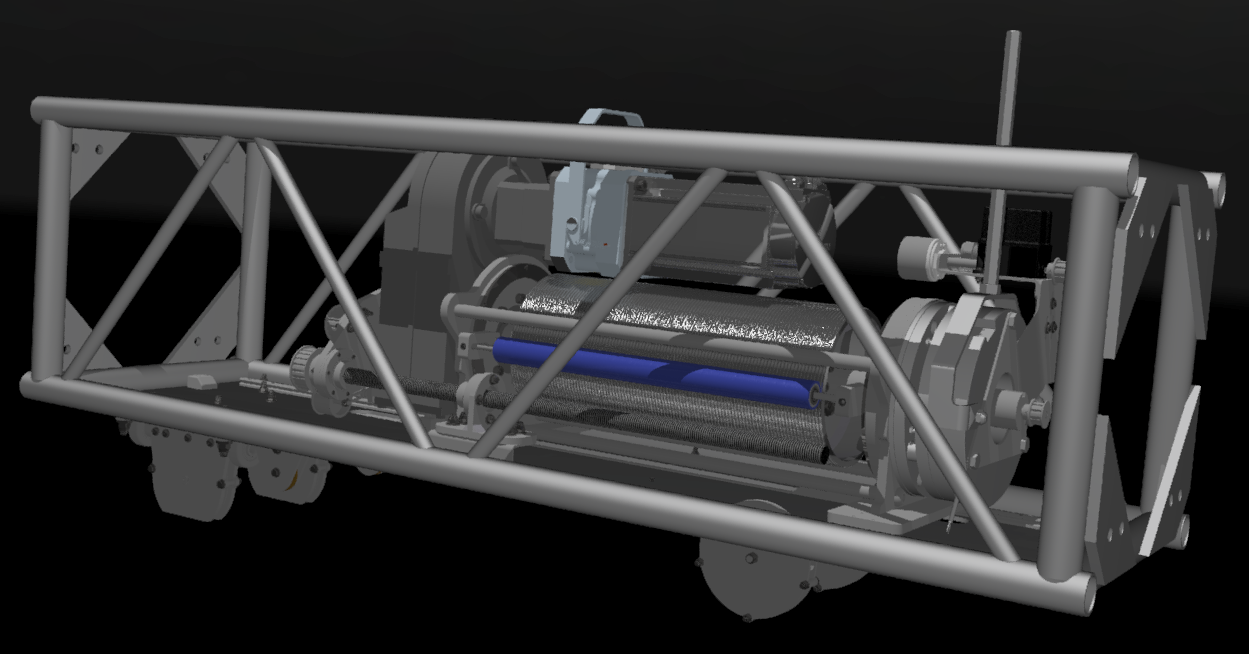

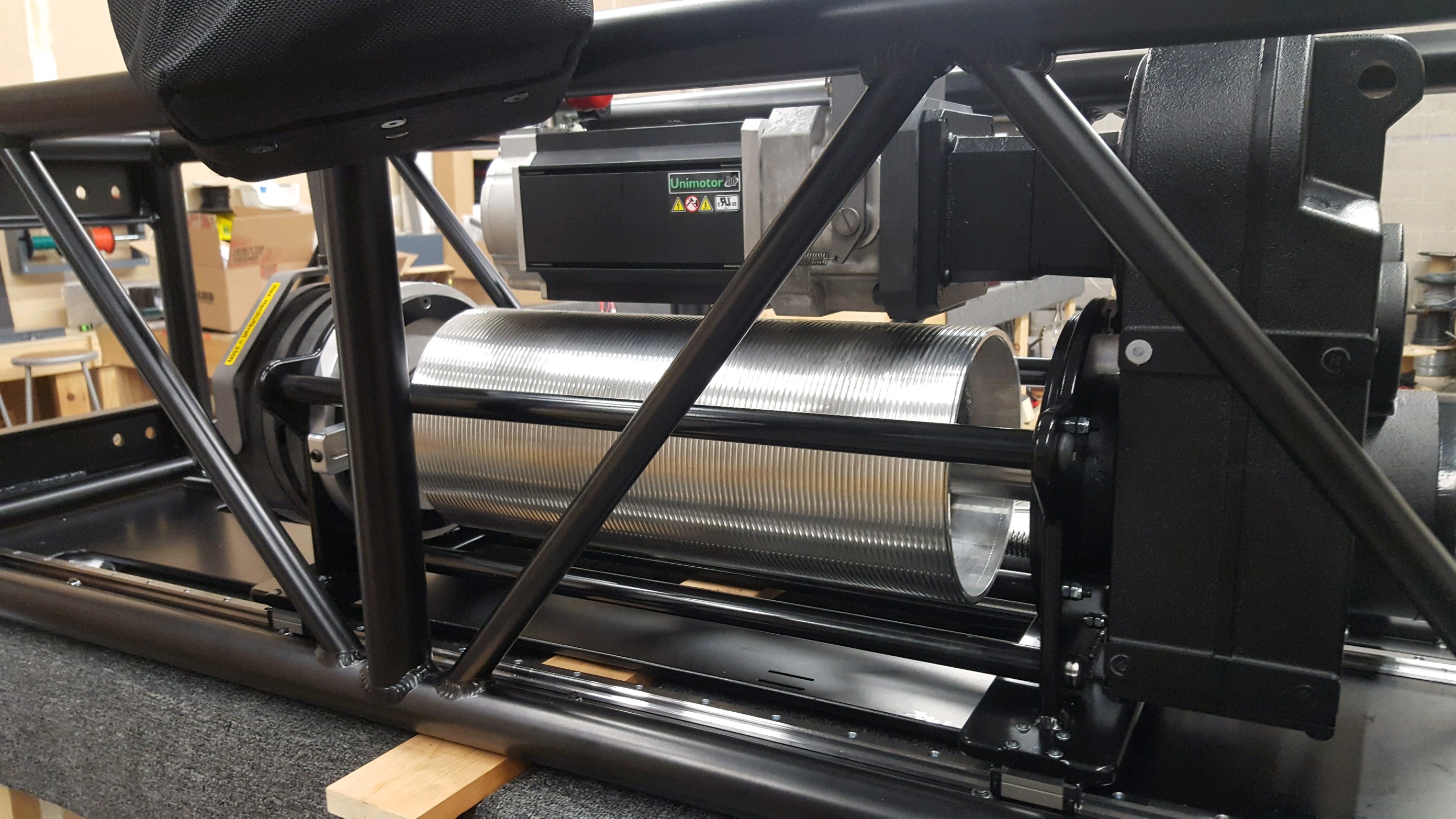

– Zero fleet hoist assembled inside a 6′ x 20.5″ box truss

– 20 – 10 – 20 AVD

– 405lb nominal line pull for a 250lb load rating

– Redundant braking with hand release levers for manual lowering

– Redundant encoders with velocity comparing for drive-train monitoring

– 4-cam rotary limit with zero fleet EOT limits

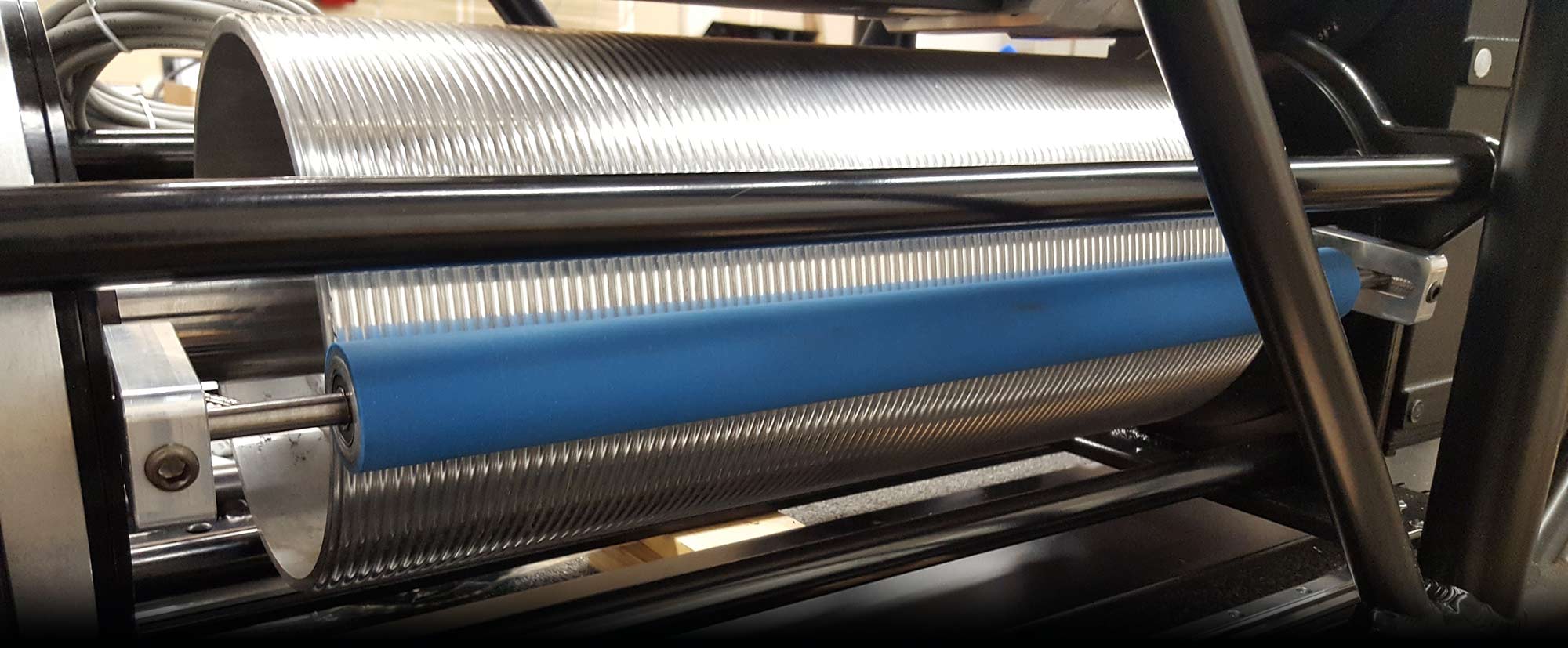

– Adjustable pinch rollers for adjustable cable exit

– Attachment points for diverter and gimbal sheaves

Case Review: PF Winch

At Verendus, we work with all types of clients ranging from schools seeking utility hoists, to touring rock and roll shows and movie production companies who are looking for fast setup and high performance. As a result of this, we need to have a variety of capabilities and be able to build machinery capable of meeting the needs of any market. Recently, one of our higher end clients had a need for a high speed flying hoist so we got work and here is what we came up with.

The PF 10-250 is a 10 fps hoist designed to meet requirements of performer flying equipment. The winch is rated for a nominal line pull of 405lbs, however, as is common with this type of hoist, it can well exceed this during acceleration and allows for a .5 second accel/decel. The braking system is designed for 250lbs giving this hoist the ability to fly a performer with whatever additional apparatus may be required and bring them to a safe stop in all scenarios. For safety, the PF 10-250 is loaded with features including a 4-cam rotary limit, dual encoders with velocity comparing, redundant braking, belt brake sensors and zero-fleet limit monitors. All of this is backed up by our own AVD software’s safety suite which includes software limits, accel/decel limits, drive status monitoring as well as a SIL3 capable safety system.

While the feature list is impressive on its own, equally impressive is the winches form factor. Through the use of a clincher style speed reducer to allow for a parallel drum and motor, we were able to fit the entire machine inside a standard 20.5” box truss. This coupled with the winches zero-fleet design allows for flexible mounting when onsite. Since the truss is a standard piece of truss, it can become an integral part of a rock and roll truss rig, or simply be mounted to another piece of hardware with standard truss clamps. We also designed a gimbal sheave system which allows flexible mounting scenarios or for a performer to fly directly off the bottom of the winch without additional rigging.

In addition to the hardware features listed above, since the PF 10-250 is controlled from our AVD software, it will only become more capable as AVD’s development continues. Also, while is AVD is a very capable control software, that does not mean it is limited to only using our control. If a client already has another control system in place, Verendus Industries is able to adapt to almost any control system on the market. For more information, please feel free to contact us at info@verendusindustries.com.